Ad Koch Modular Engineers Excel At Tackling And Solving The Toughest Separation Problems. Each tray in a distillation column is designed to promote contact between the vapor and liquid on.

Bubble Cap Tray Distillation Columns Mtl

Bubble-cap Distillation Column Design Guidelines wwwmsubbuin Column Sizing An estimate of the overall column size can be made once the number of real stages required for the.

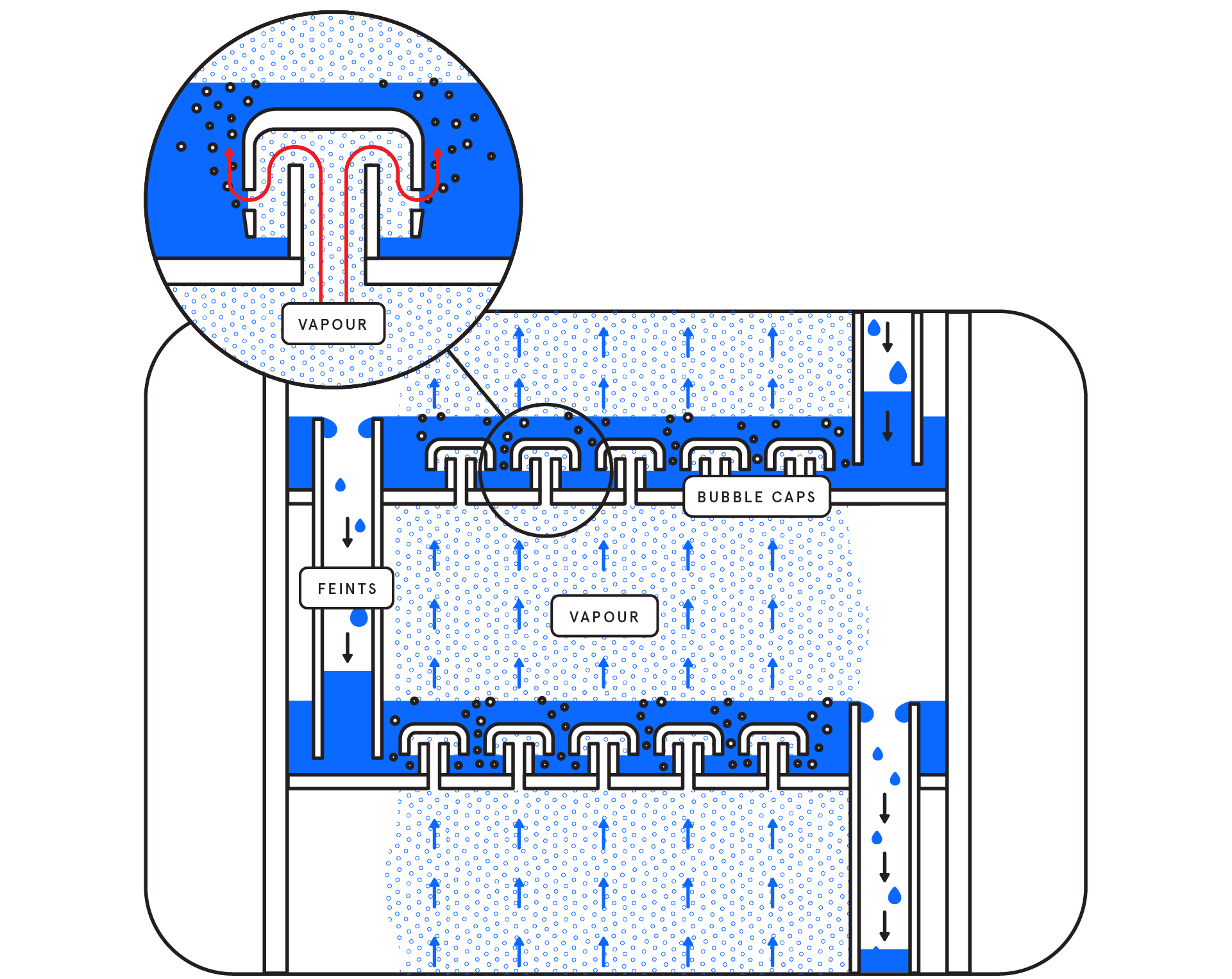

. Experts At Custom Distillation. In addition difficulties arise in large columns because of the large hydraulic. The cap is mounted so that there is a space between riser and cap to allow the passage of vapour.

Explore a wide selection of high quality laboratory equipment at competitive prices. Experts At Custom Distillation. Vapor from the still pot rises into the column and enters a pipe on the bottom of.

Large if froth is expected also allow space for crawling 12 to 24. Ad Koch Modular Engineers Excel At Tackling And Solving The Toughest Separation Problems. The trays have many holes or bubble caps like a loosened cap on a soda bottle in them to allow the vapor to pass through.

Optimize Distillation Columns dfrey1ench445 distillation column can use either trays. Bubble Cap Trays feature a riser with a cap on top allowing the vapor to flow through the rise and around the cap coming into contact with the liquid as it. You can select the Bubble cap trays and.

DISTILLATIONABSORPTION COLUMN TRAY DESIGN. Contact Koch Modular For A Quote. You have to modes in Hysys one is to design and other is rating.

You can use the tray sizing utility in Hysys for the perticular tower. ChE 4253 - Design I. The design of trays depends on the density the rate of vapor and liquid through the tray.

Distillation Column Internals an introduction COLUMN INTERNALS Trays and Plates The terms trays and plates are used interchangeably. Sieve Tray Bubble Cap Fixed Valves. Explore a wide selection of high quality laboratory equipment at competitive prices.

They increase the contact time between the vapor. Contact Koch Modular For A Quote. The trays were numbered in descending order with the top tray designated tray 1.

Design a perforated plate. Bubble-cap trays are rarely used for new installations on account of their high cost and their high pressure drop. Each tray had a diameter of.

The cap column divert the vapor flow below the level of liquid on the tray deck where it is jetted into the liquid either through slots at the bottom of the cap or else between the skirt of the cap. Valve and bubble cap trays provided critical perfor-mance data are available. Ad We are dedicated to offering personal efficient service catered to your unique needs.

Bubble-cap tray is device or packing that was mounted in a rectifying column that concentrates the alcohol. The cost of a tray column is determined by two factors. Column diameter which determines the through-put.

The distillation column contained 12 bubble cap trays spaced at 11 intervals. ChE 4253 - Design I. Such that the velocity through the holes does not form jets Number of.

There are many types of tray designs but the. Ad We are dedicated to offering personal efficient service catered to your unique needs. 316 to ¼ in.

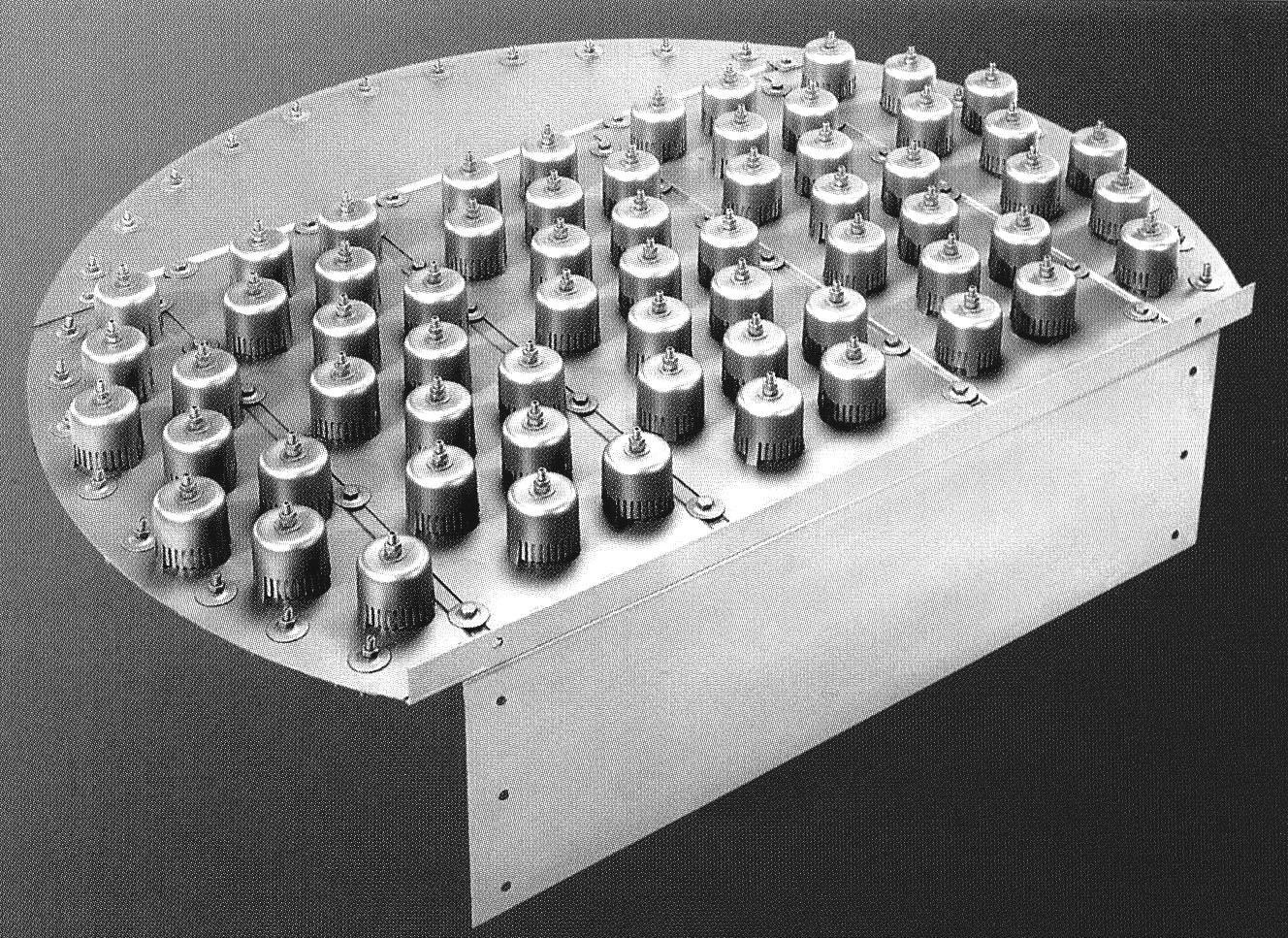

A bubble cap tray has riser or chimney fitted over each hole and a cap that covers the riser. DISTILLATIONABSORPTION COLUMN TRAY DESIGN.

Distillation Column With Bubble Cap Trays Download Scientific Diagram

File Bubble Cap Trays Png Wikimedia Commons

Plant Operations Bubble Cap Trays

Plates Trays And Bubble Caps Renegade Rum Distillery

Distillation Column Column Internals Bubble Cap Trays Valve Trays Sieve Trays Structured Packing

Distillation Column With Bubble Cap Trays Download Scientific Diagram

Distillation Column Column Internals Bubble Cap Trays Valve Trays Sieve Trays Structured Packing

Distillation Column Column Internals Bubble Cap Trays Valve Trays Sieve Trays Structured Packing

0 comments

Post a Comment